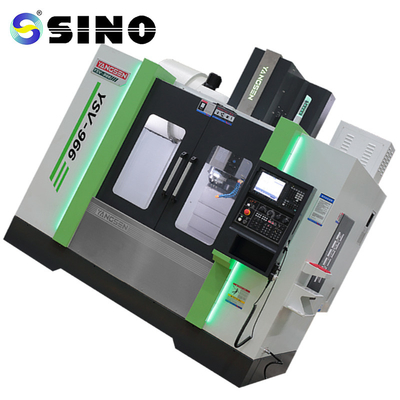

SINO YSV-966 High Precision Cutting Center CNC Milling Machine ±0.005mm High Accuracy

Machine features:

1. The Taiwan frequency conversion tool magazine is adopted, the tool change time is shortened to 1.4S, and the knife arm is controlled by the frequency converter, which effectively improves the product processing efficiency;

2. The spindle motor is equipped with a high-torque motor as standard. Outer diameter up to 150mm high rigid Taiwan BBT short nose spindle, the spindle nose has a unique labyrinth device and labyrinth blowing device to effectively protect the spindle. The maximum speed of the spindle can reach 8000rpm, which has the characteristics of high speed, high rigidity and high precision.

3. The machine tool components belong to famous brands of famous factories with high configuration.

YSV-966 optical machine features:

1. The Japanese THK line rail is adopted, and the width of Y/Z line rail reaches 45mm;

2. The Y-axis stroke is extended, up to 600mm, and the width of the worktable is widened to 570mm;

3. The X-axis sliding seat has a super-large span, and the "herringbone"-shaped column design is as stable as Mount Tai;

4. The three-axis adopts Japanese THK 40mm C3 grade screw, and the three-axis adopts NSK original bearing (3062), 3+2 mode, pre-tensioning treatment to prevent thermal displacement;

5. High-rigidity BBT spindle with outer diameter of 150mm, ring spray design;

6. Adopt Taiwan original ultra-high-speed cutting cylinder, the cutting time can reach 0.28S;

7. The bed of the machine tool is made of precision HT300 high-grade cast iron.

Standard Accessories:

1. Semi-Enclosed Guard * Swiveling Control Box

2. Auto Lubrication System * Low Energy working light

3. Volumetric Type Automatic lubricator * Transformer

4. RS 232 code * Spindle oil Coolant

5. Air Gun * Auto power off

6. Rigid tapper * Tool Box

7. Leveling Bolts and Leveling Block * Operation Manual

8. Heat Exchange for Electric Cabinet * Handwheel

9. Mechanical oil coolant separator

Optional parts

1. CTS

2. Spindle Taper ( HSK/ISO/CAT/BT )

3. Spindle RPM

4. Automatic tool changer

5. Extended Head

5. Controller option ( SINUMERIK 840D )

6. ZF Gear box or Full Gear

Product image /photos:

Installation, commissioning, acceptance, and training

1. Installation and commissioning: Our service engineer will visit the customer's plant as soon as the machine tool is delivered to do installation and commissioning as well as on-site training.

2. Customers have the option of sending operators to our company for a week or so of initial training, after which our firm will conduct on-site training at the customer's location during installation and commissioning.

3. Acceptance: Accuracy acceptance examines the items that can be examined at the customer's location and the inspection items that do not satisfy the inspection requirements, such as positioning accuracy, spindle taper hole accuracy inspection stick test, etc., in accordance with the ex-factory accuracy inspection table provided by the supplier.

For inspection and acceptance, the buyer will dispatch workers to the supplier's factory.

After-sales service concept

1. Pre-sales service: Janssen's sales representatives will present clients with the finest processing alternatives, including tool and fixture selection, option configuration, and machine tool selection.

administration of lubricating oil, cutting fluids, and other services. offering turnkey projects in addition.

2. Maintenance response time: We have a service crew of up to 26 people and a fully working service van at our disposal. As soon as we receive the user's failure notification, we will respond within two hours.

3. Parts inventory: Janssen has a specialized production facility and a full stock of parts in Xiamen. Each office maintains stockpiles of frequently used parts to provide users with the fastest repair components.

4. Maintenance of machine tools: All machine tools that are covered by a warranty period receive free maintenance services, and machine tools that are not covered by a warranty can pay affordable and fair fees for maintenance services. Plan the equipment management and maintenance process based on customer needs.

5. Maintenance fees after the warranty has expired: The standard for billing is made apparent at the actual cost, only the cost is incurred, and the user is treated with the concepts of openness, fairness, and fairness.

6. Special old user service department: closely monitor machine tool use and promptly address maintenance problems.

7. Maintenance oversight: The general manager also functions as the after-sales service department's director, monitoring the maintenance services' quality in real time and defending clients' rights.

operating environment for machines

1. 380V 10%, 15%; 50Hz 1Hz; three-phase AC power supply

2. The outside temperature is 840°C.

3. Humidity relative: 80%

4. 0.6 to 0.8 MPA for the air source pressure

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!