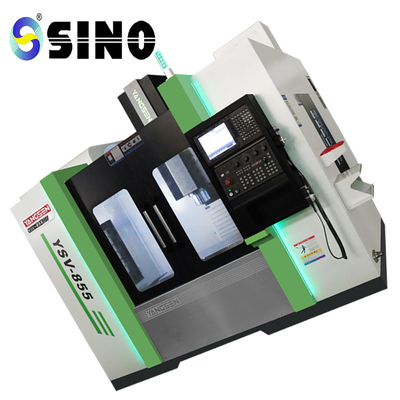

10000 r.p.m CNC Cutting Machine SINO YSV-855 3 Axes Milling Machine Center

Machine tool with exceptional performance

1. The tool change time is decreased to 1.4S using Taiwan's frequency converter tool magazine, considerably increasing processing efficiency;

2. All three axes are standard, together with quick and precise positioning and powerful torque production;

3. Compared to other brands of the same model, the spindle motor is equipped as standard with an 11–15KW high–torque generalized motor, which makes it especially ideal for heavy cutting.

4. The machine tool components are of the most cutting-edge design available in the market and are manufactured by a reputable factory under a well-known brand.

Features of optomechanisms:

Use German Rexroth/THK line rail with a maximum Y/Z line rail width of 45mm; increase the width and stroke of the worktable to 550mm and 550mm, respectively;

3. The "herringbone" column design is as stable as Mount Tai, and the X-axis movable seat has an incredibly broad spread;

4. The three axes use NSK original bearings (3062), which are pre-tensioned in the 3+2 mode, and C3 grade screws to avoid thermal displacement.

5. A 150mm-diameter, high-rigidity BBT40 spindle with a ring spray design; the machine tool's bed is made of exact HT300 high-grade cast iron; and the cutting time may reach 0.28 seconds thanks to the employment of Taiwan's original ultra-high-speed cutting cylinder.

Common Accessories:

1. Semi-Enclosed Guard * Swiveling Control Box

2. An auto lubrication system low energy operating light

3. Transformer with automated lubricator of the volumetric type

4. RS 232 code for spindle oil coolant

5. Air gun auto-off feature

6. A stiff tapper and toolbox

7. Operation Manual and Leveling Block

8. Heat exchange and a handwheel for an electric cabinet

9. A mechanical oil separator for coolant

Optional elements

1. CTS

2. (HSK/ISO/CAT/BT) Spindle Taper

Spindle RPM 3.

4. An autotool changer

5 Lengthened Head

Optional controller (SINUMERIK 840D) 6.

7. Full Gear or ZF Gear box

Product image /photos:

Installation, commissioning, training and acceptance

1. Installation and commissioning: After the machine tool arrives at the customer's factory, our service engineer will go to the customer's factory in time to carry out installation and commissioning and on-site training. 2. Customers can choose to send operators to our company to be responsible for the preliminary training for about a week, and then our company will conduct on-site training at the customer's place during installation and commissioning. 3. Acceptance: Accuracy acceptance, according to the ex-factory accuracy inspection table provided by the supplier, inspect the items that can be inspected at the customer's place, and inspect the inspection items that do not meet the inspection conditions, such as positioning accuracy, spindle taper hole accuracy inspection stick test Etc., no testing at the demand side, or negotiation between the two parties

The buyer will send personnel to the supplier's factory for inspection and acceptance.

After-sales service concept

1. Pre-sales service: Janssen's sales team will provide users with the best processing solutions, including machine tool selection, option configuration, tool and fixture selection,

Lubricating oil, cutting fluid management and other series of services. And can provide turnkey projects.

2. Maintenance response time: Our company has a service team of up to 26 people and is equipped with a complete service vehicle. After receiving the user's notification of failure, we will respond within 2 hours.

3. Parts inventory: Janssen has a special production workshop and parts inventory in Xiamen, with strong strength and complete inventory. There are commonly used parts inventories in each office to provide users with the fastest repair parts.

4. Machine tool maintenance: All machine tools within the warranty period enjoy free maintenance services, and machine tools outside the warranty period can purchase maintenance services at economical and reasonable prices. And according to customer needs, plan equipment management and maintenance process.

Machine working conditions

1. Three-phase AC power supply: 380V±10%, -15%; 50Hz±1Hz

2. Ambient temperature: 8~40Cº

3. Relative humidity: ≤80%

4. Air source pressure: 0.6~0.8 MPA

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!