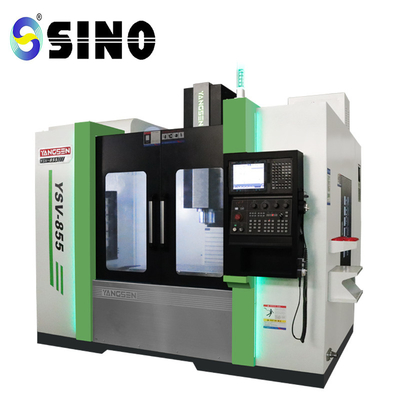

3 Axis Cnc Milling Machine Manufacturer YSV 855 Vertical Machining Center For Sale

Regular Accessory

1. (1) Semi-Enclosed Guard (2) Swiveling Control Box

2. An automobile working light for low-energy lubricating systems

3. The volumetric automated lubricator in a transformer

4. The RS 232 code for the coolant used in the spindle.

5. An auto-off feature for air guns

5. A hard tapper and a tool set

6. A balancing block and a guidebook

Excellent machine tool performance

1. By reducing tool change times to just 1.4 seconds, a Taiwanese tool magazine that uses frequency converters significantly increases processing efficiency;

2. All three axes, swift and accurate positioning, and strong torque generation are standard features;

3. The spindle motor is fitted as standard with an 11–15KW high-torque generalized motor, making it especially suitable for heavy cutting when compared to other brands of the same model.

4. The machine tool parts are created by an established company with a recognizable brand, utilizing the most cutting-edge designs currently available.

Optional elements

1. CTS

2. (HSK/ISO/CAT/BT) Spindle Taper

Spindle RPM 3.

4. An autotool changer

5 Lengthened Head

Optional controller (SINUMERIK 840D) 6.

7. Full Gear or ZF Gear box

Product image /photos:

Installation, commissioning, training and acceptance

1. Installation and commissioning: Our service engineer will visit the customer's plant as soon as the machine tool is delivered to do installation and commissioning as well as on-site training.

2. Customers have the option of sending operators to our company for a week or so of initial training, after which our firm will conduct on-site training at the customer's location during installation and commissioning.

3. Acceptance: Accuracy acceptance examines the items that can be examined at the customer's location and the inspection items that do not satisfy the inspection requirements, such as positioning accuracy, spindle taper hole accuracy inspection stick test, etc., in accordance with the ex-factory accuracy inspection table provided by the supplier.

The buyer will send personnel to the supplier's factory for inspection and acceptance.

After-sales service concept

1. Pre-sales service: Janssen's sales team will provide users with the best processing solutions, including machine tool selection, option configuration, tool and fixture selection,

Lubricating oil, cutting fluid management and other series of services. And can provide turnkey projects.

2. Maintenance response time: Our company has a service team of up to 26 people and is equipped with a complete service vehicle. After receiving the user's notification of failure, we will respond within 2 hours.

1. Three-phase AC power supply: 380V±10%, -15%; 50Hz±1Hz

2. Ambient temperature: 8~40Cº

3. Relative humidity: ≤80%

4. Air source pressure: 0.6~0.8 MPA

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!